3D Printing Terminology

Infill

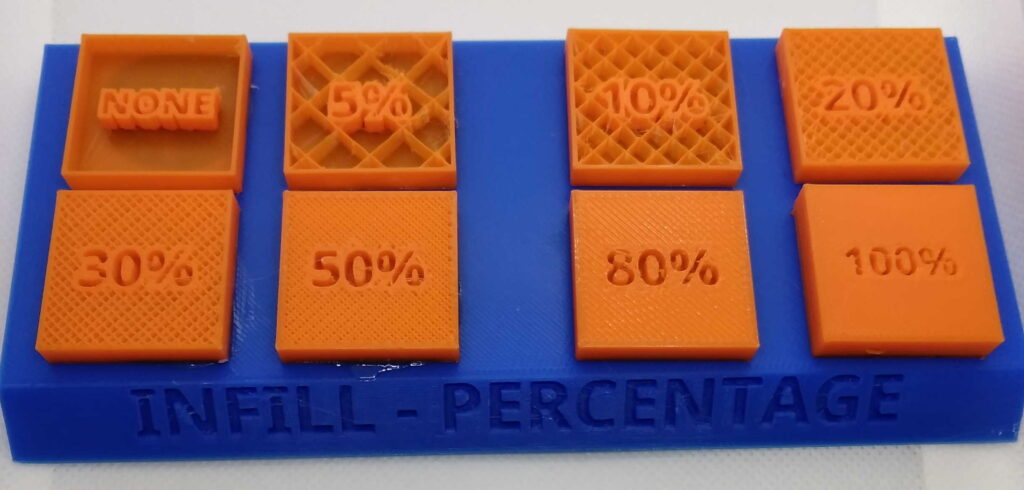

Infill is always going to be listed as a percentage between 0 and 100.

It is the volume of the “inside” expressed as a percentage.

It is difficult to tell what the infill is by just looking at an object. This is because objects almost always have solid shells. Sometimes you can hold items up to a light and see the outlines of the infill, but that is not always possible. The surest way to check infill is to weigh an item. Two items of exactly the same dimensions, printed with different infill percentages will have different weights. For example, a 20 mm cube would have these approximate weights.

| Infill | Weight |

| 20% | 4 g |

| 50% | 6 g |

| 80% | 9 g |

The higher the infill, the stronger the part will be. But at the expense of more weight, more filament used, and longer print times.

For parts that are just decorative and not load bearing an infill of 10 to 20% is usually plenty sufficient. For parts that are used functionally and would be under more stress, then 20 is probably the minimum. 50% gives reasonably good strength with a tolerable print time.

When I list 3D printed items for sale on Etsy and other platforms, I try to list the infill percent, especially if it is a functional part (ammo boxes for instance). I usually print ammo box bases at 50%, and the lid at either 20% or 50%.

I have noticed that most sellers do not post infill percents in their listings. Which always makes me skeptical that they may be using extremely low infills to save production costs and time.

If you are purchasing 3D printed items (from us or anyone else), I always suggest that you ask what the “infill percentage” is. Especially for parts that are under load. Infill is less important for things like ornaments and display models.

Shell Layers

This in is pretty much what it sounds like. The more “shells”, the thicker the outer layer. Note, that if you have 100% infill, then the shell thickness becomes moot. But most 3D prints will have something less than 100% infill. So the shell thickness also becomes a factor in the strength of the part. Most of the functional items I sell have 3 or 4 shells.

Filament

It would be impossible for me to list every available type of filament available. Many manufacturers are offering new formulations almost every week.

Below is a quick summary of some of the more popular choices. There are many more, but these are the ones you are most likely to see.

PLA filament: This has the most choices in colors, and is generally the easiest to work with. The disadvantages are that it somewhat less durable than the other choices, and it has less heat resistance. PLA items will begin to deform at about 130 F. It is one of the most popular filaments overall, and offers by far the most color choices.

PETG filament: This is a good compromise between the other PLA and ABS. It is more durable than PLA and has a higher heat resistance. These parts will not start to deform until around 170 F. PETG is also easier to print with than ABS.

ABS filament: Definitely the strongest parts. And the highest heat resistance. But more difficult to work with. It will not begin to deform until about 220 F.